Description

KUKA.Sim Pro is used for the complete offline programming of KUKA robots. This product allows the analysis of cycle times and the generation of robot programs. It also enables a real-time connection to the virtual KUKA robot controller, KUKA.OfficeLite.

KUKA.Sim Pro is used for building parametric components and defining kinematic systems which are used in KUKA.Sim Layout. KUKA.OfficeLite is included in the KUKA.Sim Pro package. By using KUKA.Sim Pro, you benefit from the following functions:

- Comprehensive, integrated CAD imports CATIA V5, JT, STEP, etc.

- 64-bit application for the highest level of CAD performance

- AVI HD video and 3D PDF export functions

- OPC UA PLC interface for Beckhoff TwinCat, CODESYS or SIEMENS PLCSIM Advanced (TIA Portal)

- KUKA.OfficeLite

KUKA. Sim

With KUKA.Sim, you can optimize the use of your systems and robots and achieve a greater level of flexibility and productivity. Future-oriented, graphical programming in a virtual environment keeps your system available for the task itself: your production process.

Functions of the KUKA.Sim software

With its intuitive user interface and a multitude of different functions and modules, KUKA.Sim provides the optimum solution and the highest degree of efficiency in offline programming.

With its intuitive user interface and a multitude of different functions and modules, KUKA.Sim provides the optimum solution and the highest degree of efficiency in offline programming.

Create layouts with ease

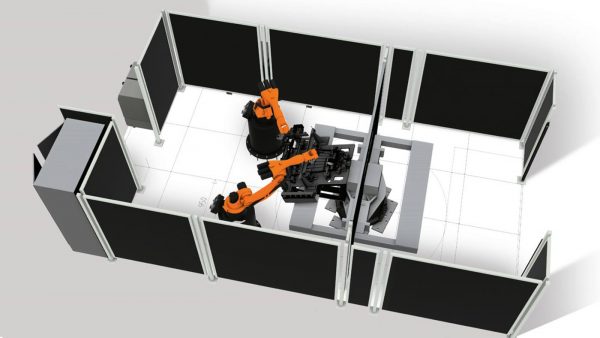

You can create optimum layouts for your production systems at an early stage of the project. Simply drag the components from the electronic catalog and place them in the required position. Investigate alternatives and verify concepts with a minimum of effort.

Electronic catalog and parametric modeling

Most of the components in the “eCatalog” are defined parametrically. This means that you can select a safety fence, for example, and adapt its height or width according to your requirements. Grippers, conveyors, safety fences and many other components are included in the electronic catalog.

Reachability check and collision detection

Reachability check and collision detection

With the reachability check and collision detection features, you can ensure the viability of your robot programs and cell layouts.

User-friendly, powerful offline programming

By writing your robot programs directly in KUKA Robot Language (KRL), you can do away with post-processors. During offline programming, tools will support you when you are calibrating workpieces. In addition, any programs created on-site can be imported into KUKA OfficeLite one-to-one, allowing you to check the programs.

Smart components – ready for Industry 4.0

You can use the KUKA.Sim software to determine cycle times in a virtual environment in advance without having to build the actual production cell. This saves you a lot of time in the planning phase. Since the program on the virtual controller is identical in every way to the software running on your real robot, the cycle times determined in KUKA.Sim are very accurate.

In addition to this, KUKA.Sim includes other comprehensive functions for designing your components intelligently, for example:

- Integration of I/O signals, sensors such as light barriers or similar physical features

- Conversion of geometries such as grippers, guns, machine tools, etc. into kinematic systems

- I/O mapping for controlling components by way of signals

This is the basis for the implementation of Industrie 4.0, ensuring greater productivity, traceable quality and data transparency.