Getting Started With The Greenhouse Sense and Control Kit

For the past week, Mia and I have been working on a new project involving a pepper plant named Pete, the SPARKvue software, and PASCO’s new Greenhouse Sense and Control Kit. Pete is a Ring of Fire pepper plant which thrives in temperatures between 26-29 degrees Celsius and a relative humidity of around 70%. We knew that we had to set up Pete’s optimal conditions if we wanted him to grow and produce any peppers, so Mia and I immediately got to work on it. We started by setting up the greenhouse itself, including the fan and grow light accessories, followed by the greenhouse sensor which includes a soil moisture probe and the temperature, humidity, and light sensing pc board. Once we connected the //control.Node to our laptop we were able to begin the programming process. Using the information available on the PASCO website, we were able to create simple code designed to regulate the temperature and relative humidity by activating the fan accessory anytime the relative humidity level went over 75% and deactivating the fan accessory once the level drops back down to 70%. This would keep the relative humidity within the desired 70-75% window. We also found that this would keep the temperature of the greenhouse between 25-26 degrees Celsius, ensuring that ideal conditions for the Ring of Fire pepper were met.

For the past week, Mia and I have been working on a new project involving a pepper plant named Pete, the SPARKvue software, and PASCO’s new Greenhouse Sense and Control Kit. Pete is a Ring of Fire pepper plant which thrives in temperatures between 26-29 degrees Celsius and a relative humidity of around 70%. We knew that we had to set up Pete’s optimal conditions if we wanted him to grow and produce any peppers, so Mia and I immediately got to work on it. We started by setting up the greenhouse itself, including the fan and grow light accessories, followed by the greenhouse sensor which includes a soil moisture probe and the temperature, humidity, and light sensing pc board. Once we connected the //control.Node to our laptop we were able to begin the programming process. Using the information available on the PASCO website, we were able to create simple code designed to regulate the temperature and relative humidity by activating the fan accessory anytime the relative humidity level went over 75% and deactivating the fan accessory once the level drops back down to 70%. This would keep the relative humidity within the desired 70-75% window. We also found that this would keep the temperature of the greenhouse between 25-26 degrees Celsius, ensuring that ideal conditions for the Ring of Fire pepper were met.

The Greenhouse Sense and Control kit contained a wide variety of equipment which allowed us to monitor the temperature and relative humidity inside the Eco Chamber. The values collected during this process helped us to create the code we needed on SPARKvue to regulate Pete’s environment easily. This code was uploaded to the //control.Node so that it would run throughout the off-hours without any constant monitoring, which was very convenient for Mia and myself, and ensured that Pete would be well taken care of in our absence.

Pete was watered manually about 3 times throughout the work week to keep him hydrated and to regulate the moisture levels of the soil, and we made sure to give him multiple hours under the grow light each day, and before long we noticed that small flower bulbs began to appear. This week, we will be focusing on maintaining the optimal environment for Pete’s success so that he continues to grow and flower. We also want to experiment more with the USB water pump, and aim to create a watering or drip irrigation system within the greenhouse!

As a future environmental engineer, I’ve truly enjoyed working with the Greenhouse Sense and Control Kit. Being able to grow a plant right here in the office has been a really great opportunity, and it’s allowed me to apply the experience gathered from my studies of soil and water to a really interesting project, as well as expand my knowledge!

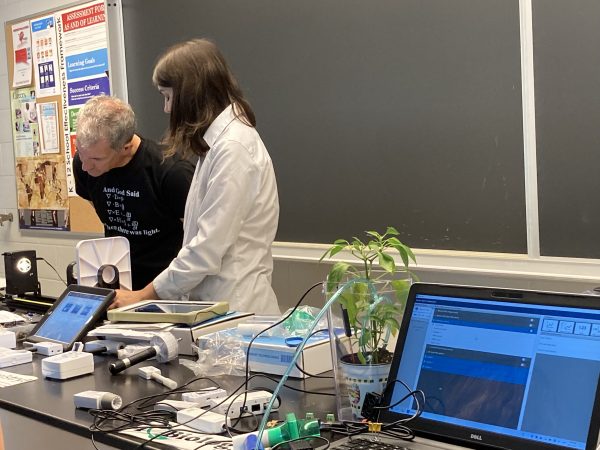

It was great to be back in person interacting with teachers! We discussed ways to integrate PASCO products into the classroom to create a fun, educational, and hands-on environment for students.

It was great to be back in person interacting with teachers! We discussed ways to integrate PASCO products into the classroom to create a fun, educational, and hands-on environment for students.

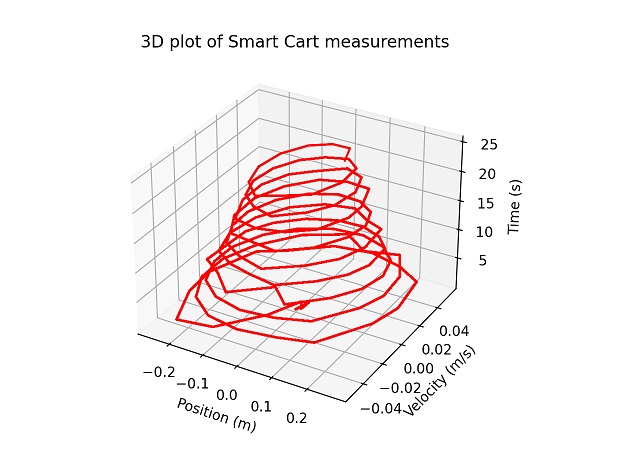

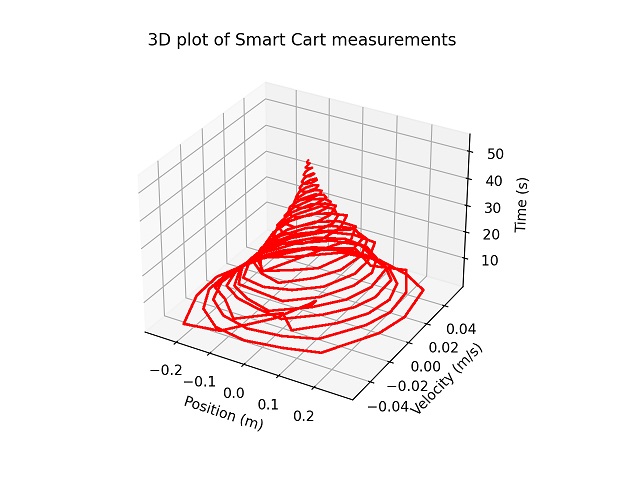

Extension: Vector Display

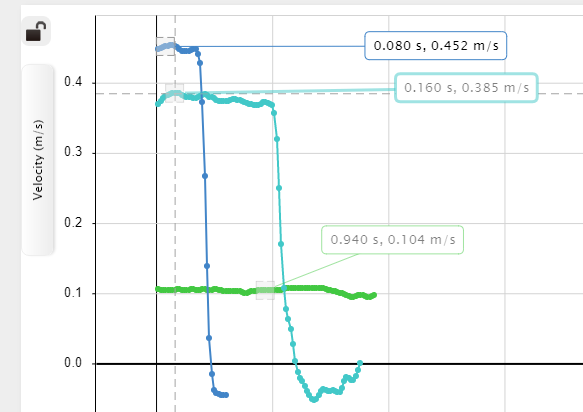

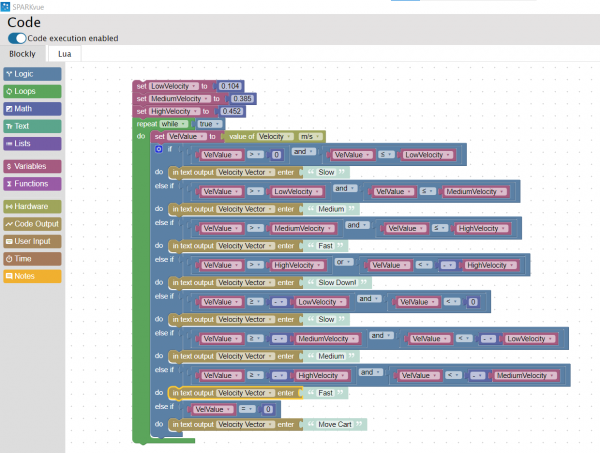

Extension: Vector Display the ones I recorded, as shown in the image on the left. I tested my code by clicking start and moving the Smart Cart. At first, I was not sure where to look for the displayed text. I realized I had to change my display from a graph to digits. Then, by clicking the variable being displayed, I switched from Sensors to User-entered and chose Velocity Vector (the variable I created in the Blockly code). This time when I pressed start, the vectors I assigned to each velocity displayed on the screen depending on the Smart Cart’s speed. I decided to change the text displayed from vectors to words. As shown in the video below, I used simple terms such as slow, medium, and fast to describe the carts’ velocities.

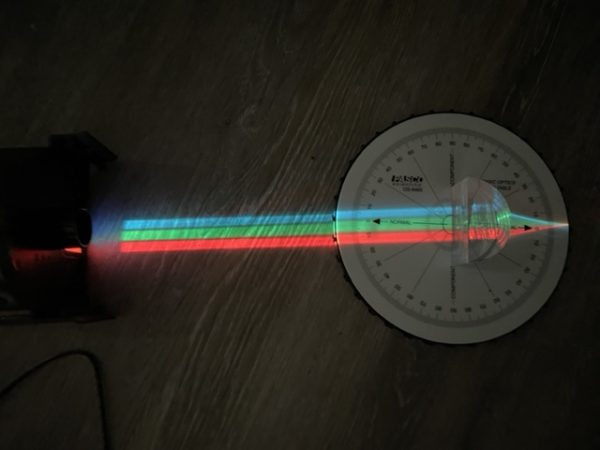

the ones I recorded, as shown in the image on the left. I tested my code by clicking start and moving the Smart Cart. At first, I was not sure where to look for the displayed text. I realized I had to change my display from a graph to digits. Then, by clicking the variable being displayed, I switched from Sensors to User-entered and chose Velocity Vector (the variable I created in the Blockly code). This time when I pressed start, the vectors I assigned to each velocity displayed on the screen depending on the Smart Cart’s speed. I decided to change the text displayed from vectors to words. As shown in the video below, I used simple terms such as slow, medium, and fast to describe the carts’ velocities. we used the Ray Table, the D-Shaped Lens, and the Light Source to perform a simple refraction experiment, using the PASCO Refraction lab as guidance as shown in the image on the left. This experiment was very easy to set up. All you need to do is plug in the Light Source and follow the instructions in the Refraction lab document. This experiment explores Snell’s Law, describing the relationship between angles of incidence and refraction.

we used the Ray Table, the D-Shaped Lens, and the Light Source to perform a simple refraction experiment, using the PASCO Refraction lab as guidance as shown in the image on the left. This experiment was very easy to set up. All you need to do is plug in the Light Source and follow the instructions in the Refraction lab document. This experiment explores Snell’s Law, describing the relationship between angles of incidence and refraction.

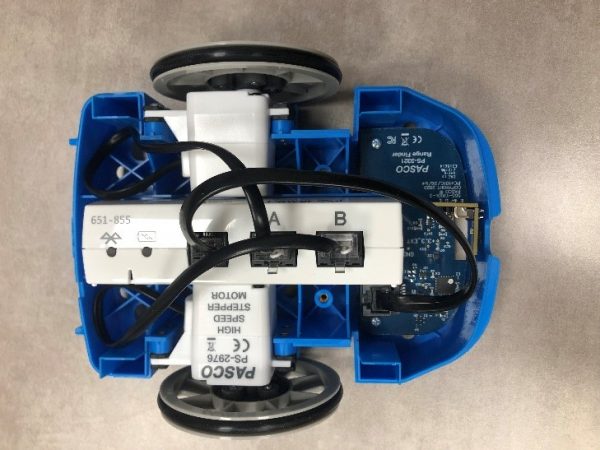

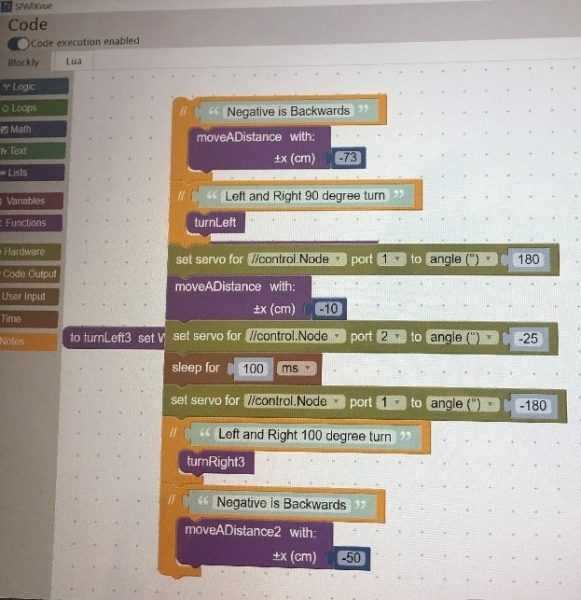

The first attachment we tested was the Gripper, shown in the photo on the left, which consists of two servo motors which attached to the //control.node. These motors allowed the Gripper to open and close its jaws as well as angle them up or down according to the given code. This was an interesting experiment that demonstrated several experimental applications of the PASCObot. For instance, setting up the code was quite simple. In the instructions, it explains how to get started with SPARKvue. The //control.node connects to the software using Bluetooth. The code is presented in a block-like manner, each instruction being in the shape of a puzzle piece. All you have to do is drag one of the puzzle pieces from the Code tool or import them from the PASCO code library, connecting them from top to bottom in the order you want them to function. Each block/puzzle piece states exactly what you want it to do. For example, to make the PASCObot move forward 50 cm, you would select the block “moveADistance with: _ cm” from the PASCO code library and type 50. Students may need a demonstration on how to navigate the code tool however, we were able to figure it out quickly, without having any previous experience with SPARKvue.

The first attachment we tested was the Gripper, shown in the photo on the left, which consists of two servo motors which attached to the //control.node. These motors allowed the Gripper to open and close its jaws as well as angle them up or down according to the given code. This was an interesting experiment that demonstrated several experimental applications of the PASCObot. For instance, setting up the code was quite simple. In the instructions, it explains how to get started with SPARKvue. The //control.node connects to the software using Bluetooth. The code is presented in a block-like manner, each instruction being in the shape of a puzzle piece. All you have to do is drag one of the puzzle pieces from the Code tool or import them from the PASCO code library, connecting them from top to bottom in the order you want them to function. Each block/puzzle piece states exactly what you want it to do. For example, to make the PASCObot move forward 50 cm, you would select the block “moveADistance with: _ cm” from the PASCO code library and type 50. Students may need a demonstration on how to navigate the code tool however, we were able to figure it out quickly, without having any previous experience with SPARKvue. This inspired us to film a short clip in which the PASCObot would move a certain distance, turn left, grab a cup of water, turn right, and bring this cup to us. We started by measuring and marking a course then coding the robot using the measurements taken, as shown in the image on the right. We were able to successfully complete this task without spilling any water, and this allowed us to become more familiar with the system.

This inspired us to film a short clip in which the PASCObot would move a certain distance, turn left, grab a cup of water, turn right, and bring this cup to us. We started by measuring and marking a course then coding the robot using the measurements taken, as shown in the image on the right. We were able to successfully complete this task without spilling any water, and this allowed us to become more familiar with the system. We then moved on to using the Range Finder Module, shown in the image on the left. This accessory was attached in the front of the PASCObot with two screws. A wire was then used to connect the Range Finder Module to the //control.node. The Range Finder Module uses infrared light to detect the distance from the PASCObot to objects. We followed the “Roving with Sight with the PASCObot” experiment from the PASCO Experiment Library and used the sample code. The code allowed the PASCObot to move on its own, avoiding objects, reacting to its surroundings, and maneuvering around the office floor independently. We found working with the PASCObot super cool and we are excited to try out more experiments.

We then moved on to using the Range Finder Module, shown in the image on the left. This accessory was attached in the front of the PASCObot with two screws. A wire was then used to connect the Range Finder Module to the //control.node. The Range Finder Module uses infrared light to detect the distance from the PASCObot to objects. We followed the “Roving with Sight with the PASCObot” experiment from the PASCO Experiment Library and used the sample code. The code allowed the PASCObot to move on its own, avoiding objects, reacting to its surroundings, and maneuvering around the office floor independently. We found working with the PASCObot super cool and we are excited to try out more experiments.