Blog Contribution, by Rob Benham, Course Leader and Senior Lecturer in Engineering Science at Southampton Solent University

The duo set out to see how the combination of this new technology could be used to optimise model design.

Vanes are made from a ‘visijet M3 crystal’ material (a thermosetting polymer with good strength and acceptable toughness for this application). Vanes were printed with 16 microns print resolution, so that fine details and intricate changes in geometry can be achieved.

For this initial research, the number of vanes included:

- Duplicated hemispherical vane (for direct comparison to the aluminium alloy type supplied)

- Domed vane based on the top half of an egg (generated by computer-aided design)

- Hemispherical vane with 1.5 mm dimples and one with 4.5 mm diameter dimples.

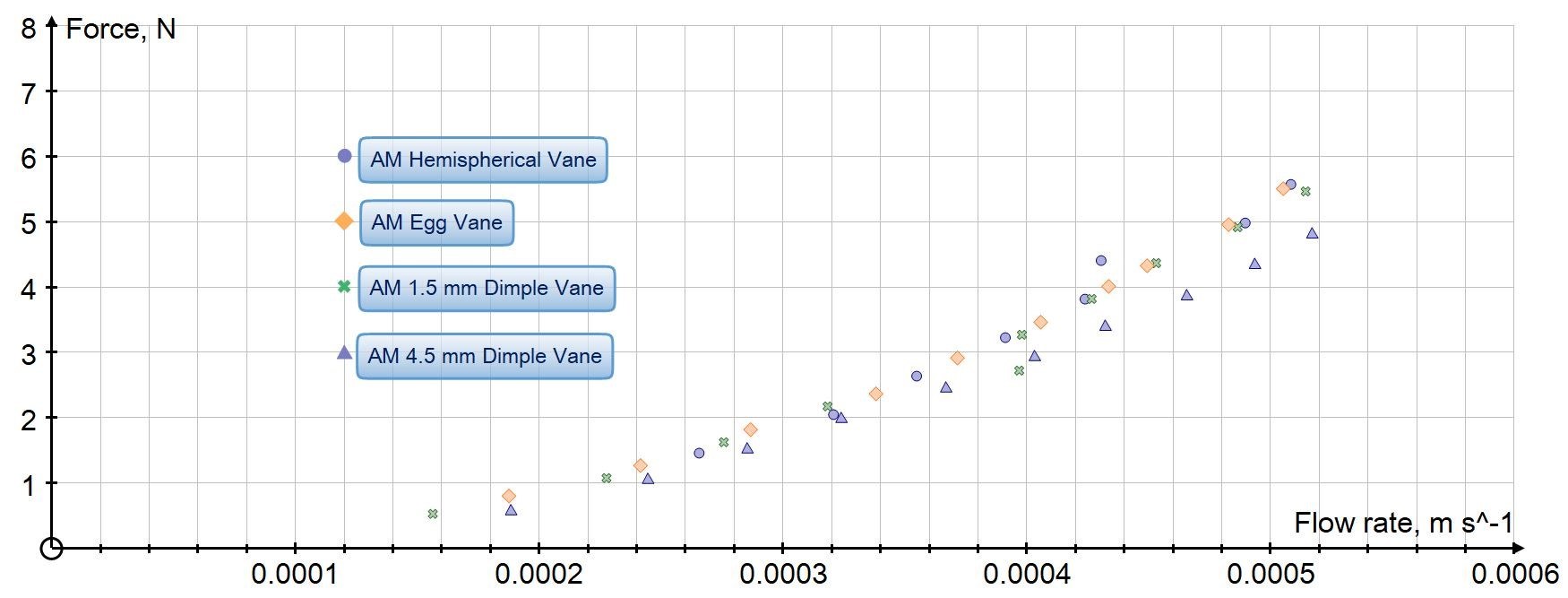

Flow rates were recorded and plotted (as shown below).

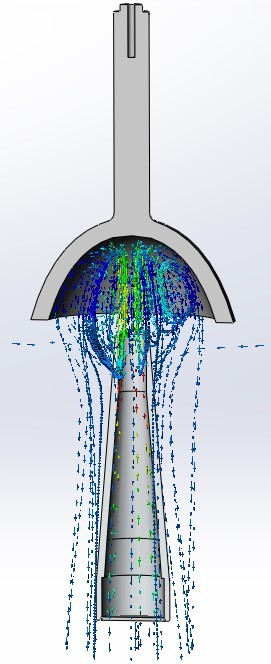

The exit profiles of the fluids differed greatly. The egg-shaped vane showing very strong similarity to the small dimpled surface, but with much less vibration on the system. At max flow the profile is very different for the egg-shaped vane, as shown below.

The system was also modelled using finite element analysis software and computational fluid dynamic modelling. Results showed very good similarity to experimental data, with excellent repeatability for this experiment. By modifying the surface with small dimples, the results are similar to an egg-shaped vane. Exit profiles of the fluids at different flow rates and vibrational amplitudes were also looked at.

Rob Benham, leading the research, says: “The CFD was particularly useful with estimating the exit velocities of the fluid, which is not possible with the complex geometries and limited with simple vane designs; the fact that the simulation showed good comparisons is promising.” His colleague, Dr Fayyaz Rehman, spent a lot of time on the simulation while Rob spent a many hours in the lab repeating the experiment with different vanes and flow rates. “In addition to this testing, there is a clear link to the exciting outcomes of TecQuipment’s Thermo-fluids Competition that was held earlier this year, since the progression of this clearly needs to focus on the nozzle design. Optimization is the next step.” Rob adds.

The research will be published in the conference proceedings at this year’s International Conference in Manufacturing Research (ICMR) 2019. This will be hosted at Queen’s University, Belfast between 10th September – 12th September 2019.