Engineering is an increasingly growing field in the UK, and it houses three of the world’s top ten universities for engineering: Imperial College London, University of Cambridge, and University of Oxford. Currently, the UK has over half a million engineers working in the country, and this number is expected to continue growing as engineering breakthroughs spur increased interest in the field.

Engineering has been the driving force behind many technological breakthroughs in the past few years. From self-driving cars, machine learning, telecommunication, and space launches – the many branches of engineering are coming together to solve many pressing societal and environmental problems of today. Elon Musk’s story, shows how revolutionising the fields of science and engineering involves merging them with entrepreneurship. And he did this on a global scale. His innovative and entrepreneurial mind spurred the development of SpaceX and Tesla, with no signs of stopping as he continues to dedicate his wealth and energies to building his vision of the future.

In the same vein, James Dyson’s background in industrial design has changed how we think about engineering. The British inventor’s vision for home innovations is a case study for experimentation and observation. He believes that we can find solutions to common problems by observing the world around us. An excellent example is how he developed the Dual Cyclone technology for his appliances – the idea came from studying how a cyclone works in nature and then applying that principle to a vacuum cleaner.

Wanda Harding is another person of interest in the field of engineering. A champion for women and people of colour in STEM, she was the senior mission manager of the Mars Curiosity Rover when it touched down on Mars in 2012. This NASA engineer and rocket scientist is directly involved in engineering education to encourage children to pursue STEM. She believes engineering classrooms should be about solving problems and learning the theory behind specific solutions.

These frontrunners are inspiring the direction that engineering education programs are heading. Many of them are designed not just to impart traditional knowledge but also to encourage the next generation of innovators across all backgrounds.

Today, we will discuss three emerging trends in engineering education:

1. Soft skills development

Besides mastering the core curriculum, engineering students must develop soft skills to excel in their professional careers. These soft skills include communication, organisational leadership, and conflict resolution. They are just as important as technical know-how when conducting day-to-day roles in their chosen industry. As engineers climb the professional ladder, they inevitably have to lead a team or mentor younger engineers in their field. Attaining success in these aspects requires having the ability to communicate clearly and effectively, solve problems quickly and manage different personalities in their teams. Knowing the pressing need for soft skills among STEM majors, forward-thinking universities such as the University of Bolton and Aston University have integrated collaboration, inclusion, and communication courses into their curricula. These subjects are designed to develop soft skills in engineering students.

2. Focus on sustainability

Sustainability is a critical pillar of contemporary engineering education. Today, there is an emphasis on integrating the humanities and the engineering sciences to install a desire in students to attempt to solve environmental and societal problems. This kind of collaboration is a growing trend in professional spaces. For instance, The Guardian assembled a team of software engineers and reporters to build tools for climate reporting. A deeper understanding of sustainability needs an interdisciplinary approach, which can only be done when sustainability is integrated into engineering curriculums. To achieve this, UK universities with engineering programs such as the University of Leeds have linked up with environmental bodies such as the Centre for Climate Change Economics and Policy.

3. Emphasis on diversity

Diversity is a pressing problem in the field of engineering. It is an area historically dominated by white, middle, or upper-class men, but engineering education is starting to reshape this reality. Harnessing the diverse talent of the UK’s society requires proactive effort from educational institutions. Schools like the Royal Academy of Engineering have made strides in this aspect by investing more in their diversity and inclusion action plans and partnering with key organisations such as the Women’s Engineering Society and LGBTQ+ networks for engineers in the UK. These efforts are actually amounting to concrete results, with Engineering UK noting an increase in the number of women employed within the engineering sector.

Leveraging the potential of engineering to solve the world’s most complex problems involves a constant transformation of engineering education. These trends demonstrate that UK engineers today are not armed with technical acumen; they are also prepared to create a more inclusive, prosperous, and sustainable world.

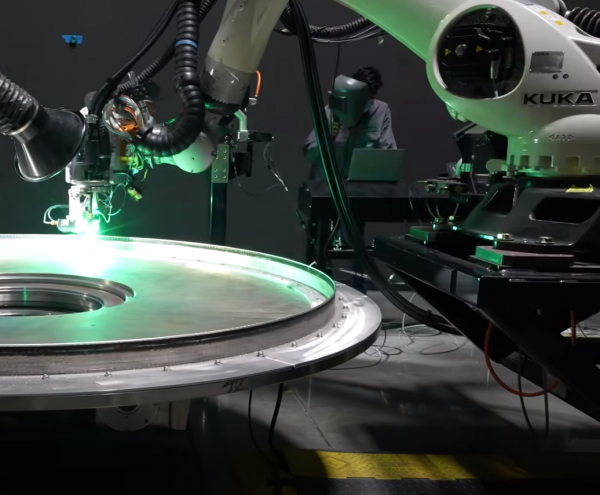

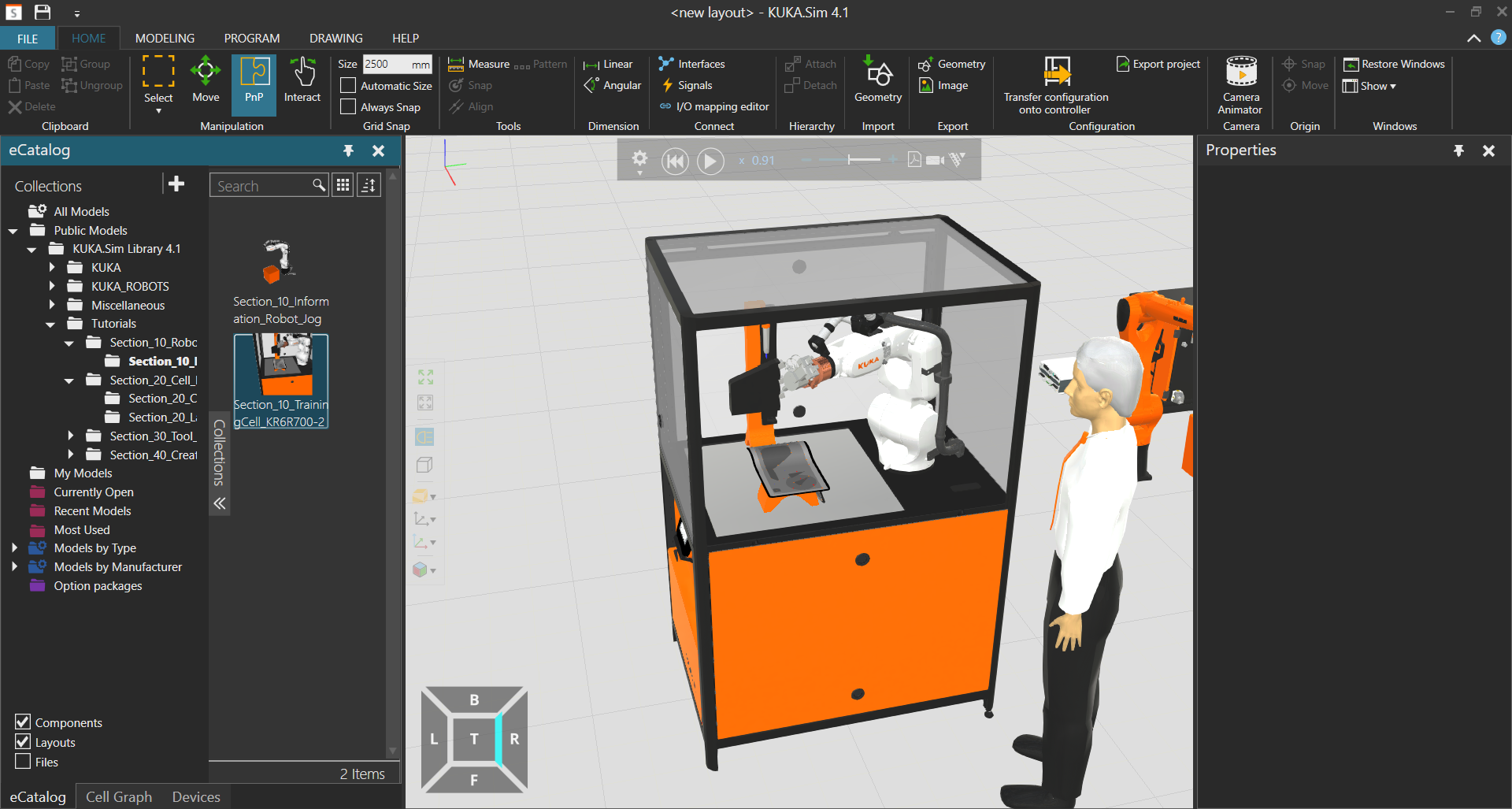

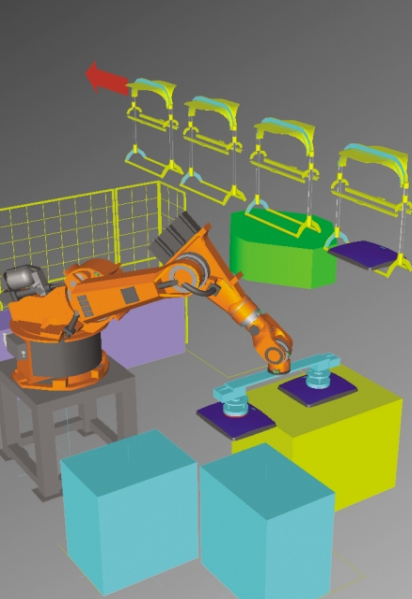

This comprehensive software package allows students to optimize the operation of manufacturingsystems and robots outside of a production environment. Creating a digital ‘twin’ of a production process in just a few minutes, without a deep programming knowledge.

This comprehensive software package allows students to optimize the operation of manufacturingsystems and robots outside of a production environment. Creating a digital ‘twin’ of a production process in just a few minutes, without a deep programming knowledge.

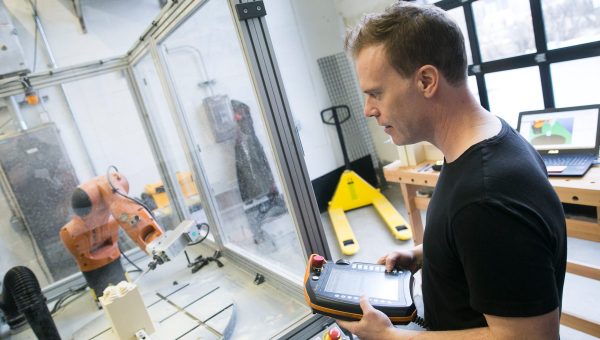

The CIMS team will use the robots to assist in creating sculptures and other architectural ornaments in a variety of materials — including stone and wood — from digital models obtained by laser scanning and photogrammetry, the science of using photographs to make precise measurements.

The CIMS team will use the robots to assist in creating sculptures and other architectural ornaments in a variety of materials — including stone and wood — from digital models obtained by laser scanning and photogrammetry, the science of using photographs to make precise measurements.