Description

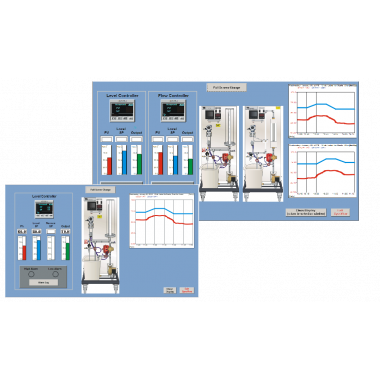

A self-contained mobile module for flow process control experiments to illustrate the principles of single-loop control and the calibration & tuning of controllers, transmitters, converters and valves. Demonstrates feedback control, P/PI/PID control and flow control. Cascade control experiments available when used with the optional pressure or level process training systems. Distributed control available when used with optional computer control system.

The Flow Process Training System is a compact and mobile unit for a wide range of experiments in flow control. It gives students a greater understanding of the stability of simple control systems.

The self-contained unit can do many experiments, but it can also connect to other products in the TE3300 range for extra experiments. For cascade control of flow and pressure, it can link to the optional Pressure Process Training System (TE3300/02). For cascade control of flow and level, it can link to the optional Level Process Training System (TE3300/04). For distributed control, it can connect to the optional Computer Control System (TE3300/06).

The main parts of the Flow Process Training System are:

- Industrial controller with auto-tune feature

- Two-channel chart recorder

- A gap-type (rotameter) flow meter

- Fixed orifice and pressure transmitter

- Pneumatic control valve

- Three-speed pump

- Reservoir

To perform experiments, students fill the reservoir with clean water and prime the system. They then set the controller to regulate the flow of the water using a pneumatic valve. The gap-type flow meter gives a visual indication of flow. The fixed orifice and pressure transmitter give feedback to the controller.

For a realistic experience, the equipment has industrial standard instrumentation and parts.

The apparatus includes two gate valves. One valve controls the flow at the output (drain) and the other acts as a flow-bypass valve. A chart recorder shows and logs the changes of the process variable (flow) and the controller output.

Key features:

- Shows automatic control of flow using proportional, proportional plus integral, and proportional, integral plus derivative (PID) control

- Uses industry-standard parts to make it ideal for industrial, vocational and academic training

- Shows operation, calibration and tuning of controllers, transmitters, converters and valves

- Compact, mobile and fully self-contained

- Connects to the TE3300/02 Pressure Process and TE3300/04 Level Process Training Systems for cascade control

- Connects to the TE3300/06 Computer Control System for distributed control

- Safe, practical and realistic

Learning outcomes:

- Proportional, integral and derivative control

- Setting up and demonstrating automatic control

- The principles of loop control and the calibration and tuning of controllers, transmitters, converters and valves

- Calibration of an orifice flow meter with a differential pressure transmitter

- Quadratic flow laws and square root extraction

- Cascade control of pressure and flow, and level and flow (when used with the TE3300/02 and TE3300/04)

- Distributed control (when used with the TE3300/06 Computer Control System)